On January 12, 2025, Professor Guohao Fang's research group published a paper titled “Behavior of the interfacial transition zone in AAFS-based green recycled aggregate concrete at elevated temperatures” (a top journal in the field, classified as Q1 by the Chinese Academy of Sciences). The study reveals the microstructural changes in the interfacial transition zone (ITZ) of alkali-activated fly ash-slag-based green recycled aggregate concrete (AAFS-RAC) under elevated temperatures and its impact on mechanical properties. The findings provide a theoretical basis for optimizing AAFS-RAC for high-temperature applications and propose potential directions for ITZ modification to enhance performance. Ruixi Li and Xuan Tang, undergraduates from the Class of 2021 at the Institute of Advanced Study at Shenzhen University, are the first and second authors, respectively. Professor Guohao Fang from the Institute of Advanced Study at Shenzhen University is the corresponding author, with Shenzhen University as the primary institution.

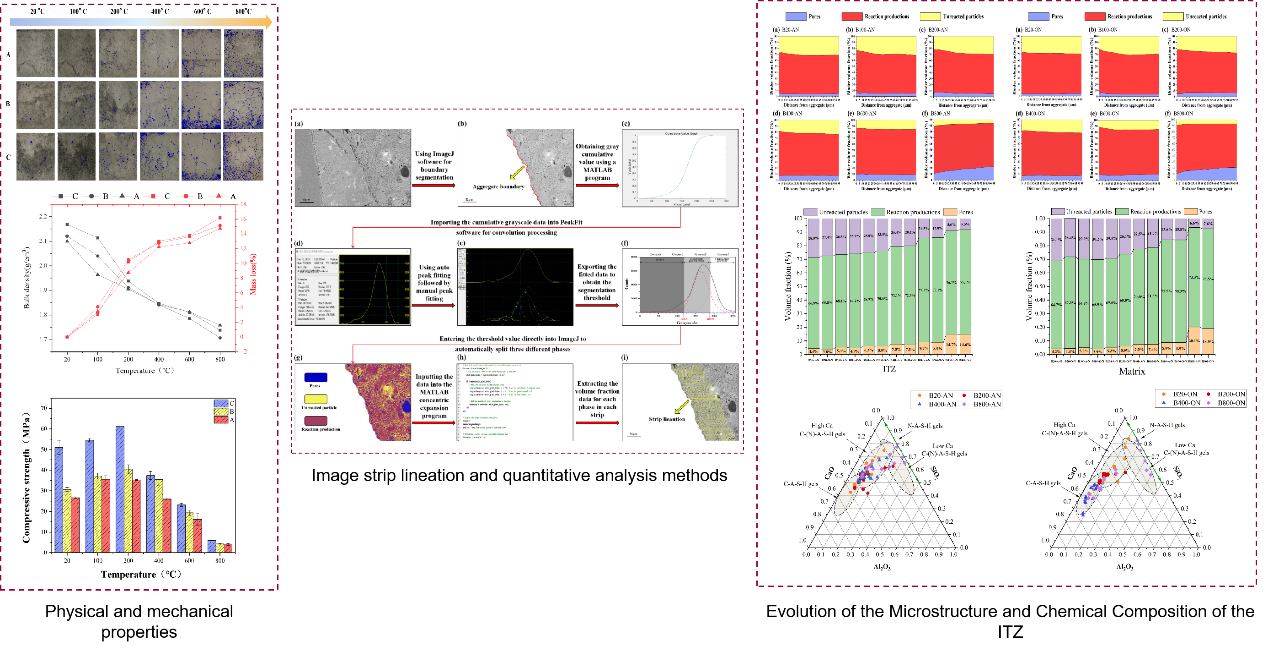

AAFS-RAC is an eco-friendly alternative for Portland cement concrete (PCC). Nonetheless, the current understanding of its microstructural performance at elevated temperatures, especially concerning the complex ITZ with recycled aggregates (RA), remains insufficiently explored. This study systematically investigated the physical and mechanical properties of AAFS-RAC containing recycled coarse and fine aggregates from crushed PCC at temperatures ranging from 20°C to 800°C. Microstructural analysis was conducted using SEM, BSEM, and EDS to examine two ITZ types: the A-N interface (unbound aggregate and new paste) and the O-N interface (old paste and new paste). The results revealed that while the compressive strength of each mixture initially rose with temperature, peaking at 200°C before sharply declining above 600°C , the mix with 25% slag demonstrated the highest residual strength. Below 400°C, the O-N ITZ had a higher volume fraction of reaction products, particularly C-A-S-H and high-calcium C-(N)-A-S-H gels, as well as a lower porosity in contrast to the A-N ITZ, enhancing the microstructure. Above 400°C, porosity increased in both interfaces, with matrix damage exceeding ITZ degradation. The expansion of interface cracks between the aggregates and the ITZ, along with the progressive formation of pores and the decomposition of gels in the matrix, contributed to the decline in high-temperature performance.

This research was supported by the National Key Research and Development Program, National Natural Science Foundation and Shenzhen Key Laboratory for Low-carbon Construction Material and Technology.

The original article can be found at:https://authors.elsevier.com/c/1kQIr3O1E1c0C2