On February 13, 2025, Professor Guohao Fang's research group published a paper titled “Investigation of "internal-external" enhanced method for recycled aggregate” (a top journal in the field, classified as Q1 by the Chinese Academy of Sciences). This paper presents an "internal-external" enhanced pretreatment technology for recycled aggregates (RA), which improves the microstructural and mechanical properties of RA through internal filling repair and external surface modification. The multi-interface enhancement further enhances the performance of recycled aggregate concrete (RAC). Weicong Luo, a graduate student from the Class of 2022 at the Institute of Advanced Study, Shenzhen University, is the first author. Professor Guohao Fang from the Institute of Advanced Study at Shenzhen University is the corresponding author, with Shenzhen University as the primary institution.

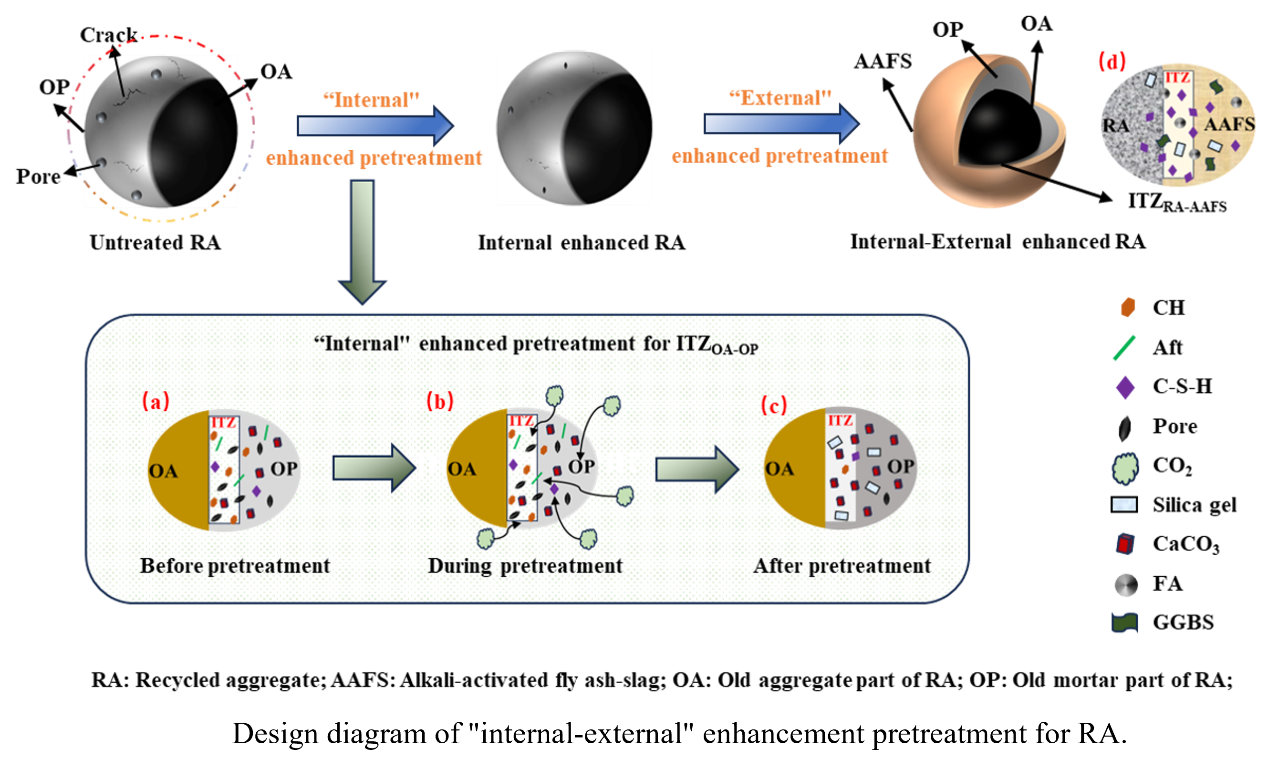

The use of RA as a substitute for natural aggregate (NA) in concrete production offers significant potential in addressing the environmental pollution associated with RA and the resource scarcity of NA. However, compared to NA, RA typically exhibit characteristics such as lower density, higher water absorption, increased porosity, and numerous microcracks.These characteristics are mainly attributed to the weak old mortar that remains bonded to their surfaces.To address this, the present study proposes an "internal-external" enhanced pretreatment technique for RA.By characterizing the microstructure and interfacial mechanical properties of RA and RAC before and after the "internal-external" pretreatment, this study investigates the enhancement mechanisms and identifies the optimal process conditions. The results reveal that during the "internal-external" pretreatment, significant carbonation products are formed through reactions with carbon dioxide, effectively filling and repairing the micro-porous structure of the RA. Furthermore, the RA surface is coated with a layer of alkali-activated fly ash-slag slurry, which provides structural support and forms a high-performance interfacial transition zone with the new mortar in the RAC. Under the influence of the "internal-external" pretreatment, both the microstructural and mechanical properties of RA and RAC are significantly improved. The optimal efficiency and effectiveness of the "internal-external" pretreatment are achieved under conditions of 70N-CH3 "internal" pretreatment and 50S-0.4–1 M "external" pretreatment.

This research was supported by the National Key Research and Development Program, National Natural Science Foundation and Shenzhen Key Laboratory for Low-carbon Construction Material and Technology.

The original article can be found at:https://doi.org/10.1016/j.conbuildmat.2025.140405