On July 6, 2025, the Professor Guohao Fang research group published a research paper titled " Engineering properties of strain-hardening geopolymer composites reinforced with various natural fibers: Multiscale synergistic optimization and sustainability" in the Journal of Construction and Building Materials (JCR Q1). This study comprehensively investigated the feasibility of replacing polyethylene (PE) fibers with natural fibers (NF) to develop EGC with superior mechanical properties, cost-effectiveness and environmental sustainability. Professor Guohao Fang and Professor Hui Zhong are the joint corresponding authors, and Shenzhen University is the first completion unit.

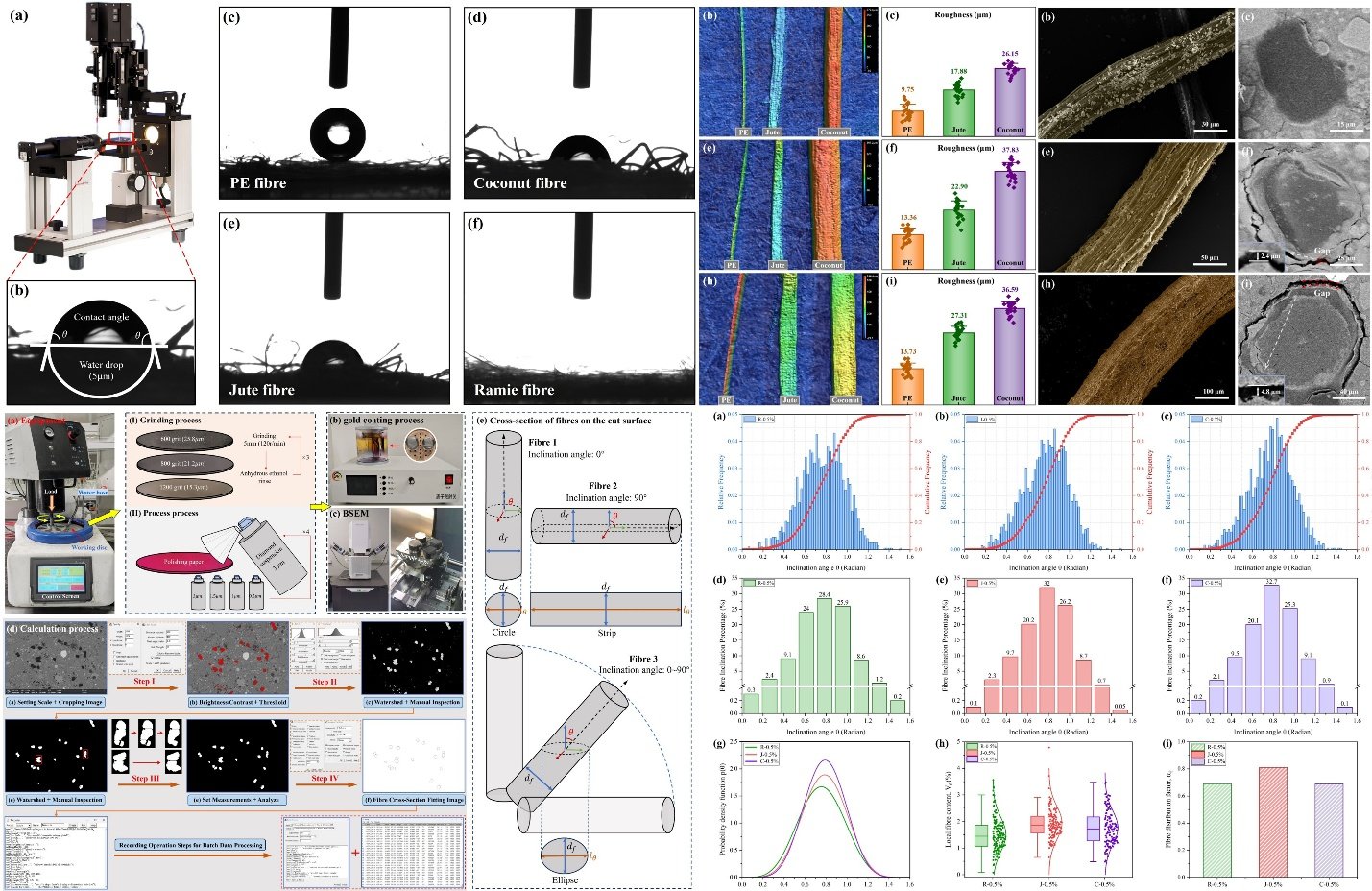

This study comprehensively investigated the feasibility of replacing PE fibers with NF to develop EGC with superior engineering properties, with a special focus on the effects of three NF types (jute, ramie, and coconut fibers) on mechanical properties, fiber-matrix interface behavior and microstructure of EGC. X-ray computed tomography (XCT) and backscattered electron microscopy (BSEM) were employed to analyze the internal microstructure, including pore structure and fiber distribution. Results indicate that the EGC mix showed pronounced strain-hardening and multiple cracking behavior when 0.5 % PE fiber was replaced with NF, attributed to the improved fiber-matrix interfacial properties and enhanced fiber distribution. EGC with 0.5 % jute fiber outperformed other hybrid fiber reinforced mixes in terms of compressive strength (85.4 MPa), tensile strength (6.6 MPa) and tensile strain capacity (6.5 %), comparable to those of single fiber reinforced mixes. The material cost, embodied carbon and embodied energy of EGC with NF were decreased by up to 73 %, 5 % and 26 %, respectively, as compared to EGC with solely PE fibers. This study provides a potential pathway for developing high-strength, cost-effective, and environmentally friendly green building materials, expanding the application of NF-EGC to address complex environmental demands.

This research was supported by the National Natural Science Foundation and Shenzhen Key Laboratory for Low-carbon Construction Material and Technology.

The original article can be found at:

https://doi.org/10.1016/j.conbuildmat.2025.142423

Fig.1. NF-EGC with high-strength and extraordinary tensile ductility.