On 26.7.2023, Professor Jiang worked with the research team from Changchun Institute of Applied Chemistry Chinese Academy of Sciences (CIAC) together to publish a research paper entitled " A Universal Approach to Fabricating 3D Chemical Patterns for Directed Self-assembly of Block Copolymers with Density Multiplication " in Macromolecules (Q1, IF: 5.5). In this work, they reported a universal and fab-compatible approach to fabricating 3D chemical patterns for DSA of BCPs with density multiplication by combining lithographic patterning and plasma treatment. Professor Jiang, Professor Song from Shenzhen University and Professor Ji from CIAC are co-corresponding authors.

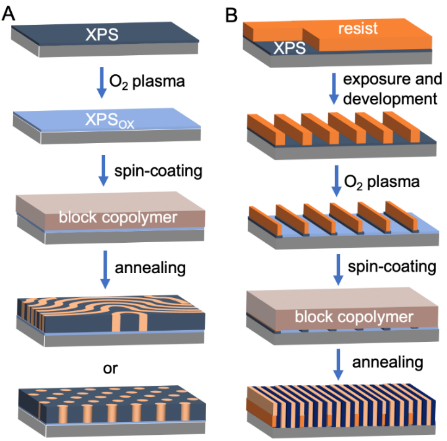

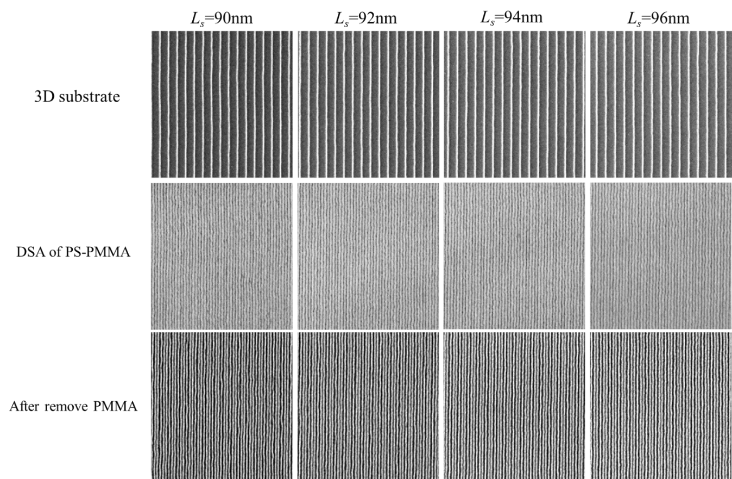

Directed self-assembly (DSA) of block copolymers (BCPs) with density multiplication has been proved to be a viable technique for the fabrication of FinFET at 7nm node, due to it offers a cost-effective solution to enhance the performance of current 193 nm immersion lithography technology, and has recently undergone a transition from laboratory to industrial scale for high volume manufacturing. The key to the realization of DSA with density multiplication is to control the interfacial energy between BCP and the underlying substrate. The surface energy of cross-linked polystyrene (XPS) mat could be tuned for controlling the wetting behavior of BCP films by simply adjusting oxygen plasma treatment conditions. Non-preferential surfaces for poly (styrene-b-methyl methacrylate) (PS-b-PMMA), poly (styrene-b-methyl acrylate) (PS-b-PMA), poly (styrene-b-propylene carbonate) (PS-b-PPC) and poly (styrene‑b‑(lactic acid-alt-glycolic acid)) (PS-b-PGLA) are obtained by oxygen plasma treatment, which eliminates the use of random copolymer brushes in the LiNe flow. 3D chemical patterns are successfully fabricated by combining eBeam negative patterning of PMMA photoresist and oxygen plasma treatment, and DSA of lamellae-forming PS-b-PMMA and PS-b-PMA with up to 10x density multiplication is achieved on 3D chemical patterns.

The original article can be found at:https://doi.org/10.1021/acs.macromol.3c00417

Fig.1 Schematic process of (A) self-assembly of BCPs on the plasma-treated XPS mat and (B) DSA of BCPs on the 3D chemical pattern with density multiplication, and SEM images of DSA of PS-b-PMMA film on 3D chemical patterns with Ls=90,92,94 and 96nm.